The debate surrounding polystyrene recycling vs polypropylene recycling is critical in the context of environmental sustainability and resource management. Both polystyrene and polypropylene are ubiquitous in daily life, serving as materials for a wide range of products, from food containers to automotive parts. This article delves into the complexities of recycling these plastics, discussing their respective processes, benefits, and drawbacks. By examining the key differences and similarities, as well as the specific circumstances that favor one type of recycling over the other, we aim to provide a clear understanding of the role these materials play in our recycling systems and their potential impact on the environment.

What is the Main Difference Between Polystyrene and Polypropylene Recycling?

The main difference between polystyrene and polypropylene recycling is that polystyrene, commonly known as Styrofoam, is a foam product characterized by its lightweight and insulating properties, making its recycling process more challenging due to contamination issues, volume-to-weight ratio, and the cost of transportation. Polystyrene often requires compacting or densifying before it can be economically recycled. On the other hand, polypropylene is a more resilient and less brittle type of plastic, commonly used in packaging, textiles, and automotive parts, which can be more readily recycled through melting and reprocessing into new products. Polypropylene recycling generally encounters fewer issues with contamination and is less voluminous, making it a more straightforward and cost-effective material to recycle.

What are Polystyrene and Polypropylene Recycling?

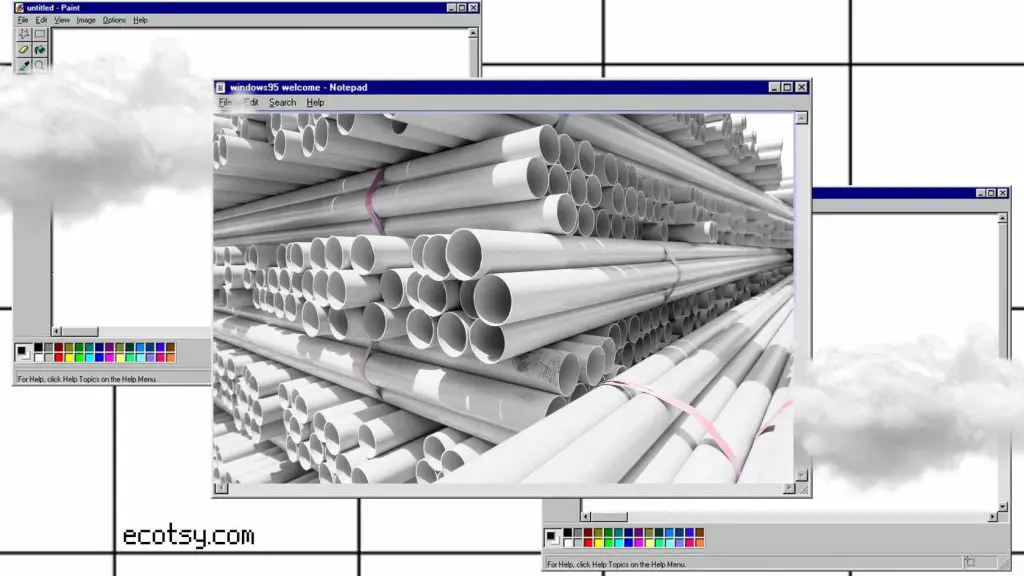

Polystyrene recycling involves the process of reprocessing polystyrene, a type of plastic marked with the resin identification code 6. Polystyrene is commonly used for products like foam cups, take-out food containers, egg cartons, and packaging materials. Due to its lightweight and insulating properties, polystyrene is prevalent in the food service and packaging industries. Recycling polystyrene can be challenging because of its bulkiness and the fact that it is often contaminated with food waste. However, with proper cleaning and processing, it can be transformed into new materials such as insulation boards, picture frames, and office supplies.

Polypropylene recycling refers to the reclamation process of polypropylene, a thermoplastic polymer identified by the resin identification code 5. Polypropylene is known for its toughness, resistance to chemicals, and versatility. It is widely used in products such as yogurt containers, plastic furniture, automotive parts, and textiles. Polypropylene is one of the more recyclable plastics and can be melted and reformed into new products multiple times. Recycled polypropylene can be used to create items like garden planters, storage bins, and automotive parts.

Key Differences Between Polystyrene and Polypropylene Recycling

- Recycling Symbol: Polystyrene is labeled with the number 6 recycling symbol, while polypropylene carries the number 5.

- Recycling Rate: Polystyrene is less commonly recycled than polypropylene due to logistical and economic constraints.

- Material Properties: Polypropylene is more resistant to heat and chemicals compared to polystyrene, affecting their respective recycling processes.

- Recycling Process: The recycling process for polystyrene often includes compacting to reduce volume, while polypropylene can be directly ground into flakes after sorting.

- End-Product Usage: Recycled polystyrene is typically used for making lower-grade products like packing materials, whereas recycled polypropylene can be utilized in manufacturing higher-grade items such as automotive parts.

- Market Demand: The demand for recycled polypropylene is generally higher than for recycled polystyrene, which affects the economic viability of their respective recycling streams.

- Contamination Sensitivity: Polystyrene recycling is more sensitive to contamination by food waste, making it more challenging to recycle effectively.

- Energy Consumption: The energy required to recycle polystyrene can be higher due to its low density, leading to larger volumes of material to process.

Key Similarities Between Polystyrene and Polypropylene Recycling

- Resin Identification Codes: Both polystyrene and polypropylene are marked with resin identification codes to facilitate sorting and recycling.

- Thermal Processes: Both types of plastics undergo thermal processes such as melting and extrusion during recycling.

- Eco-Friendly Goals: Recycling both polystyrene and polypropylene supports environmental sustainability by reducing the need for virgin materials and decreasing landfill waste.

- Post-Consumer Products: Both can be recycled from post-consumer products, such as packaging and food containers.

- Mechanical Recycling: Both polystyrene and polypropylene are typically recycled using mechanical procedures, including grinding, washing, and melting.

- Secondary Markets: Recycled polystyrene and polypropylene have established secondary markets, although the scale and demand may vary.

- Quality Degradation: With each recycling loop, both polystyrene and polypropylene may experience some degradation in quality, which can limit the number of times they can be recycled.

Advantages of Recycling Polystyrene Over Polypropylene

- Energy Efficiency: Polystyrene recycling often requires less energy compared to polypropylene due to the different processes involved. The recycling of polystyrene can be done through a process called compaction, which is less energy-intensive than the melting process required for polypropylene.

- Volume Reduction: Polystyrene products, especially expanded polystyrene (EPS), can be bulky. Recycling helps to significantly reduce the volume of waste, as polystyrene can be compacted to a fraction of its original size, making it more efficient to transport and store.

- Material Versatility: Recycled polystyrene can be used in a variety of applications, including insulation, picture frames, and architectural molding. This versatility can create a broader market for recycled polystyrene products.

- Chemical Recycling Potential: Polystyrene has the potential for chemical recycling, where the material is broken down into its original monomers for repolymerization. This can create a closed-loop system, potentially leading to a more sustainable recycling process.

- Lower Contamination Rates: Polystyrene recycling processes can be less sensitive to contamination compared to polypropylene. This means a wider range of post-consumer polystyrene can be accepted, reducing the amount sent to landfills.

- Economic Benefits: There is a growing market for recycled polystyrene, which can provide economic incentives for recyclers and manufacturers. This can lead to job creation and economic growth in the recycling sector.

- Easier Identification: Polystyrene items are generally easier to identify due to the resin identification code “”6,”” which can streamline the sorting process and improve recycling rates.

- Lower Water Usage: Recycling polystyrene typically requires less water than recycling polypropylene. Since water scarcity is a growing global issue, reduced water usage in the recycling process is a significant benefit.

Disadvantages of Recycling Polystyrene Compared to Polypropylene

- Limited Collection Infrastructure: Polystyrene recycling programs are not as widespread as those for polypropylene, which may limit the availability of recycling services for consumers and businesses.

- Public Perception: Polystyrene often has a negative public image due to its association with single-use items and visible litter. This perception can impact consumer participation in recycling programs and lead to less material being recycled.

- End-Product Quality: Recycled polystyrene may not always match the quality of virgin polystyrene or recycled polypropylene. This can limit its use in some high-quality applications, potentially reducing market demand.

- Health and Safety Concerns: The recycling of polystyrene can release styrene, a potential carcinogen, posing health risks to workers. Adequate safety measures must be in place, which can increase operational costs.

- Economic Viability: The cost-effectiveness of recycling polystyrene can be a concern, as the process may not always be profitable without subsidies or incentives, unlike some polypropylene recycling operations.

- Degradation During Recycling: Polystyrene can degrade during the recycling process, which may limit the number of times it can be recycled compared to polypropylene.

- Environmental Impact: While recycling reduces the environmental impact of polystyrene, the production and disposal of polystyrene still pose significant environmental concerns, such as the potential for microplastics pollution.

- Market Fluctuations: The market for recycled polystyrene can be volatile, influenced by oil prices and demand for virgin material. This can make investments in recycling infrastructure riskier compared to the more stable market for polypropylene.

Advantages of Recycling Polypropylene Over Polystyrene

- Lower Melting Point: Polypropylene has a lower melting point compared to polystyrene, which means it requires less energy to process during recycling. This energy efficiency can lead to cost savings and a reduced carbon footprint.

- Durability: Recycled polypropylene maintains its strength and durability, making it ideal for producing a wide range of products from automotive parts to reusable containers, whereas polystyrene often becomes more brittle after recycling.

- Versatility: Polypropylene can be recycled into various forms such as fibers and filaments, expanding its utility across different industries. Polystyrene’s applications after recycling are more limited.

- Non-Toxic: When polypropylene is recycled, it does not release harmful chemicals. Polystyrene, on the other hand, may leach styrene, a potential human carcinogen, especially when heated.

- Market Demand: There is a higher market demand for recycled polypropylene due to its broader range of applications, which can make the recycling process more economically viable than polystyrene recycling.

- Ease of Separation: Polypropylene is easier to separate from other plastics during the recycling process, which increases the efficiency and purity of the recycled material. Polystyrene often requires more intensive sorting.

- Lower Toxicity During Production: The production of polypropylene typically involves less toxic substances than polystyrene production, which can lead to a safer recycling process and fewer environmental hazards.

- Higher Recycle Rate: Polypropylene has a higher recycling rate compared to polystyrene, which means a greater proportion of polypropylene waste is being reused and diverted from landfills.

Challenges of Recycling Polypropylene Compared to Polystyrene

- Collection and Sorting: While polypropylene is easier to separate from other plastics, the collection and initial sorting can be more challenging because it is often used in a wider variety of products, leading to a more diverse waste stream.

- Contamination Sensitivity: Polypropylene can be more sensitive to food and other organic contaminations, which can complicate the recycling process and require additional cleaning steps compared to polystyrene.

- End-of-Life Options: Although polypropylene can be recycled, there are fewer facilities equipped to handle end-of-life polypropylene compared to polystyrene, which can limit recycling opportunities.

- Recycling Infrastructure: The infrastructure for recycling polypropylene is not as well-developed as for polystyrene in some regions, which can result in lower recycling rates for polypropylene despite its advantages.

- Color Sorting: Recycled polypropylene often needs to be color sorted to produce a high-quality recycled product. This is not as critical for polystyrene, which can be a transparent or solid color.

- Quality Degradation: Each time polypropylene is recycled, the quality of the plastic can degrade, potentially limiting its recyclability after several cycles. While polystyrene also degrades, certain recycling methods like chemical recycling can mitigate this issue.

- Market Prices: The market prices for recycled polypropylene can be more volatile than for polystyrene, affecting the economic stability of recycling programs.

- Heat Sensitivity: Polypropylene is more sensitive to high temperatures during the recycling process, which can cause melting or warping if not carefully controlled, whereas polystyrene has a higher tolerance for heat during recycling.

Circumstances Favoring Polystyrene Recycling Over Polypropylene

- Energy Efficiency: Polystyrene recycling can sometimes be more energy-efficient compared to polypropylene because of the lower temperatures required to process the material.

- Single-Use Items: For single-use items like disposable cups and plates, polystyrene recycling is more beneficial since these items are often not made from polypropylene.

- Insulation Materials: Polystyrene is widely used in insulation products. Recycling polystyrene insulation is often more practical than recycling polypropylene as there are fewer applications for recycled polypropylene in this sector.

- Food Service Industry: Polystyrene is commonly used for food packaging due to its insulation properties. Recycling programs for these items are better suited for polystyrene to prevent contamination and maintain food safety.

- Impact Resistance: Polystyrene items that require high impact resistance, such as CD cases, are better recycled to maintain the quality and characteristics needed for similar products.

- Protective Packaging: Since polystyrene is prevalent in protective packaging for electronics and other fragile items, recycling efforts are more effective in this area than for polypropylene.

- Medical Supplies: Certain medical supplies made of polystyrene are better recycled under controlled conditions to ensure that they are safely repurposed or disposed of, contrary to polypropylene which may not be as common in this application.

- Compliance with Regulations: In regions where regulations favor the recycling of polystyrene due to environmental concerns or disposal issues, it makes more sense to focus on polystyrene recycling.

- Economic Value: If the market demand for recycled polystyrene is higher than for polypropylene, recycling programs may prioritize polystyrene to maximize economic returns.

Situations Favoring Polypropylene Recycling Over Polystyrene

- Durability of Recycled Products: Polypropylene can often be recycled into more durable products than polystyrene, making it the preferred material in situations where strength and longevity are required.

- Automotive Parts: In the automotive industry, polypropylene is widely used for various components. Recycling polypropylene is more advantageous here due to the high quality of the recycled material needed.

- High-Temperature Applications: For applications involving higher temperatures, recycling polypropylene is preferable, as it has a higher melting point compared to polystyrene.

- Food Containers: Polypropylene is often used in reusable food containers. These can be recycled more effectively than polystyrene containers, which are typically designed for single use.

- Medical Equipment: Unlike certain medical supplies where polystyrene is preferable, larger pieces of medical equipment often use polypropylene, which is better suited for recycling due to its robustness and ability to be sterilized.

- Outdoor Applications: Polypropylene is more resistant to UV light and weather conditions, making the recycling of outdoor items like garden furniture or plant pots more suited to polypropylene.

- Fiber and Textile Industry: The recycling of polypropylene is more beneficial for producing industrial fibers and textiles, as it can be made into a variety of fabrics and materials for different uses.

- Lower Contamination Risk: Polypropylene is less likely to leach harmful chemicals upon recycling, making it a safer choice for consumer products.

- Hygienic Products: Due to its hygienic properties, polypropylene is often used in the production of diapers and sanitary products. Recycling these items is typically more effective with polypropylene.

- Environmental Impact: If a life cycle analysis shows that polypropylene has a lower environmental impact when recycled compared to polystyrene, it would be the preferred material for recycling initiatives.

FAQs

Can polystyrene be recycled at home?

No, polystyrene recycling is not typically a process that can be done at home. It requires specialized equipment to compact or melt the material, which is usually only available at industrial recycling facilities. Consumers are encouraged to clean and deposit polystyrene materials at appropriate recycling centers or drop-off locations.

What are the environmental benefits of recycling polypropylene?

Recycling polypropylene reduces the reliance on petroleum as a source of raw material, conserves energy, and decreases greenhouse gas emissions from the production of new plastics. It also helps to minimize the amount of plastic waste that ends up in landfills or as environmental pollutants in oceans and waterways.

How can consumers identify polystyrene and polypropylene items for recycling?

Consumers can identify polystyrene items by looking for the resin identification code “6” usually stamped on the product. Polypropylene items are marked with the code “5.” These symbols are often found on the bottom of containers and packaging.

What are some common misconceptions about plastic recycling?

A common misconception is that all plastics are equally recyclable. In reality, the recyclability of plastic depends on its resin type, presence of contaminants, local recycling capabilities, and market demand for the recycled material. Another misconception is that all items with a recycling symbol are accepted in local curbside recycling programs, which is not always the case.

Does the color of polystyrene or polypropylene affect its recyclability?

The color of polystyrene does not significantly affect its recyclability as it is often used to make products that don’t require clear or natural colors. However, for polypropylene, the color can affect recyclability since color sorting may be necessary to produce a high-quality recycled product. Clear or natural-colored polypropylene is more desirable in the recycling market.

Is recycled polystyrene safe to use in food packaging?

Recycled polystyrene can be safe for food packaging if it undergoes proper cleaning and processing to remove contaminants. However, regulations may vary by region, and some places may not allow recycled polystyrene to be used in direct contact with food without an additional virgin layer to act as a barrier.

How does the compaction process work for polystyrene recycling?

The compaction process for polystyrene involves crushing and compressing the foam material to reduce its volume significantly. This makes it easier to handle, transport, and store. Compacted polystyrene can then be fed into a pelletizing machine to be melted and extruded into new plastic products.

Polystyrene vs Polypropylene Recycling Summary

Polystyrene and polypropylene recycling each come with their own set of advantages and challenges. While polystyrene recycling can be more energy-efficient and is beneficial for specific applications such as insulation materials, it faces issues like negative public perception and limited end-product quality. Conversely, polypropylene recycling boasts a higher market demand and can lead to more durable recycled products, but it requires a well-developed infrastructure to address its diverse waste stream. Recognizing the nuances of polystyrene recycling vs polypropylene recycling is essential for developing effective waste management strategies, driving innovation in recycling technologies, and ultimately moving towards a more sustainable future.

| Aspect | Polystyrene Recycling | Polypropylene Recycling |

|---|---|---|

| Recycling Symbol | #6 | #5 |

| Common Uses | Foam cups, food containers, packaging | Yogurt containers, plastic furniture, automotive parts |

| Recycling Rate | Lower due to logistical and economic constraints | Higher, more commonly recycled |

| Material Properties | Less resistant to heat and chemicals | More resistant to heat and chemicals |

| Recycling Process | Compaction to reduce volume, sensitive to contamination | Grinding into flakes after sorting, less sensitive to contamination |

| End-Product Usage | Lower-grade products like packing materials | Higher-grade items like automotive parts |

| Market Demand | Generally lower | Generally higher |

| Energy Consumption | Higher due to bulkiness and low density | Lower due to lower melting point |

| Pros | Potential for chemical recycling, versatility in applications | Maintains strength and durability, non-toxic, broad applications |

| Cons | Limited collection infrastructure, negative public perception | More challenging initial sorting, sensitive to contamination |

| Similarities | Both undergo thermal processes, support reducing landfill waste | Both undergo thermal processes, support reducing landfill waste |

| Situations Favoring Recycling | Insulation materials, food service industry, protective packaging | Durable products, automotive parts, high-temperature applications |